Most Common Metal Building Insulation Materials

Posted on Tuesday May 07, 2024 at 03:28PM in General

Metal buildings are unique in the way they are insulated. Unlike conventional commercial construction, a typical metal building insulation application includes an exposed vapor retarder which faces toward the interior of the building, plus an insulation material and system accessories. Metal building insulation comes in a variety of material types; from fiberglass and mineral wool to rigid foam board and insulated metal panels, there are many insulation options for metal buildings today. Several factors should be considered when deciding which insulation material is best for a project, including end-use of the building, energy code requirements, and project budget.

Why Insulate a Metal Building?

Not all metal buildings need insulation. Structures such as simple metal garages, barns and storage sheds often do not require insulation. Determining whether a metal building needs insulation should include a variety of factors, such as the location and climate of your project, as well as the end-use of the building.

Because metal is a strong conductor of heat, the majority of metal buildings in the U.S. are insulated. Hot and cold air easily enter and escape metal buildings, which means insulation is crucial in maintaining a comfortable indoor temperature in hot and cold climates. Additionally, insulation protects metal buildings from condensation, which occurs when warmer air comes in contact with cold surfaces, such as framing members and windows, or the colder region within the building envelope if moisture has penetrated the vapor retarder. A typical metal building insulation application also improves energy efficiency, reduces noise transfer, and provides a finished interior appearance.

How to Choose Metal Building Insulation Material

The first step in deciding which metal building insulation material is best for your project is to evaluate the following factors:

- 1. End-use of the building, which significantly impacts the type of insulation system and vapor retarder selected. Climate control requirements and building characteristics are two important considerations in selecting a metal building insulation system. Swimming pools and agricultural facilities, for example, have specific requirements for consistent condensation and temperature control. Building characteristics, such as roof pitch, should also be taken into account when choosing an insulation material, as low-slope roofs require a system that provides adequate support and prevents sagging.

- 2. Project budget is a key consideration, as the cost of different metal building insulation materials varies considerably. Fiberglass rolls, or batts, tend to offer the lowest cost per square foot, while insulated metal panels are typically the most expensive. Additionally, contractors should factor in labor costs when considering which insulation material is best for a project. Insulated metal panels require the use of heavy equipment during installation, whereas fiberglass rolls and many rigid board products can be installed without additional equipment and with only one or two laborers. It’s important to factor in both material and labor costs when considering the overall R-value vs. cost value for a particular metal building insulation system.

- 3. Commercial energy codes dictate the minimum amount of insulation required in metal buildings. The first step in determining the minimum R-value necessary for a project includes checking your state or local jurisdiction’s adopted energy code. Some states, such as Washington, have their own code, though the majority of states follow either the IECC code or the ASHRAE 90.1 Standard. More recent commercial energy code cycles, such as IECC 2021/ASHRAE 90.1-2019, require more insulation than older code cycles. The minimum amount of insulation needed for a project is specified in the roof and walls prescriptive U-Factors tables of each published commercial energy code/Standard.

The next step in deciding which metal building insulation material is best for a project includes understanding the key differences between each material type:

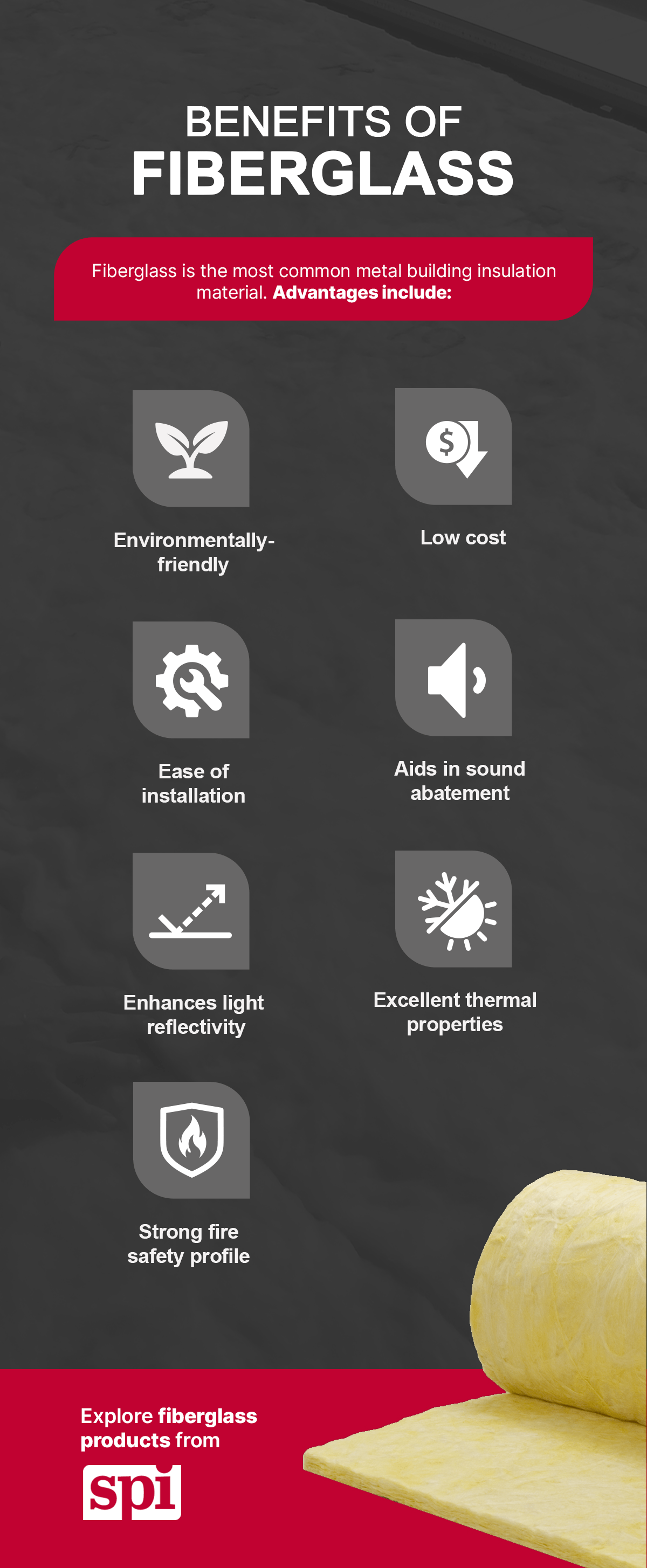

Fiberglass

Fiberglass insulation is the most common metal building insulation material type due to its low cost, ease of installation, and strong fire safety profile. Other advantages of fiberglass metal building insulation include:

- •Excellent thermal properties which help reduce the building’s operating costs for heating and air conditioning

- •Aids in sound abatement

- •Environmentally-friendly

- •Enhances light reflectivity and may reduce lighting costs

Fiberglass comes in a variety of options for metal building roofs and walls, including:

- •Unfaced, which can be used to fill cavities or as part of a larger fiberglass system

- •Laminated insulation includes a vapor retarder adhered to a layer of fiberglass

- •High-R fiberglass systems, which are gaining in popularity due to increasingly stringent energy code requirements, typically include two layers of fiberglass plus banding and accessories. The two most common types of high-R fiberglass systems are Liner Systems and Filled Cavity Systems.

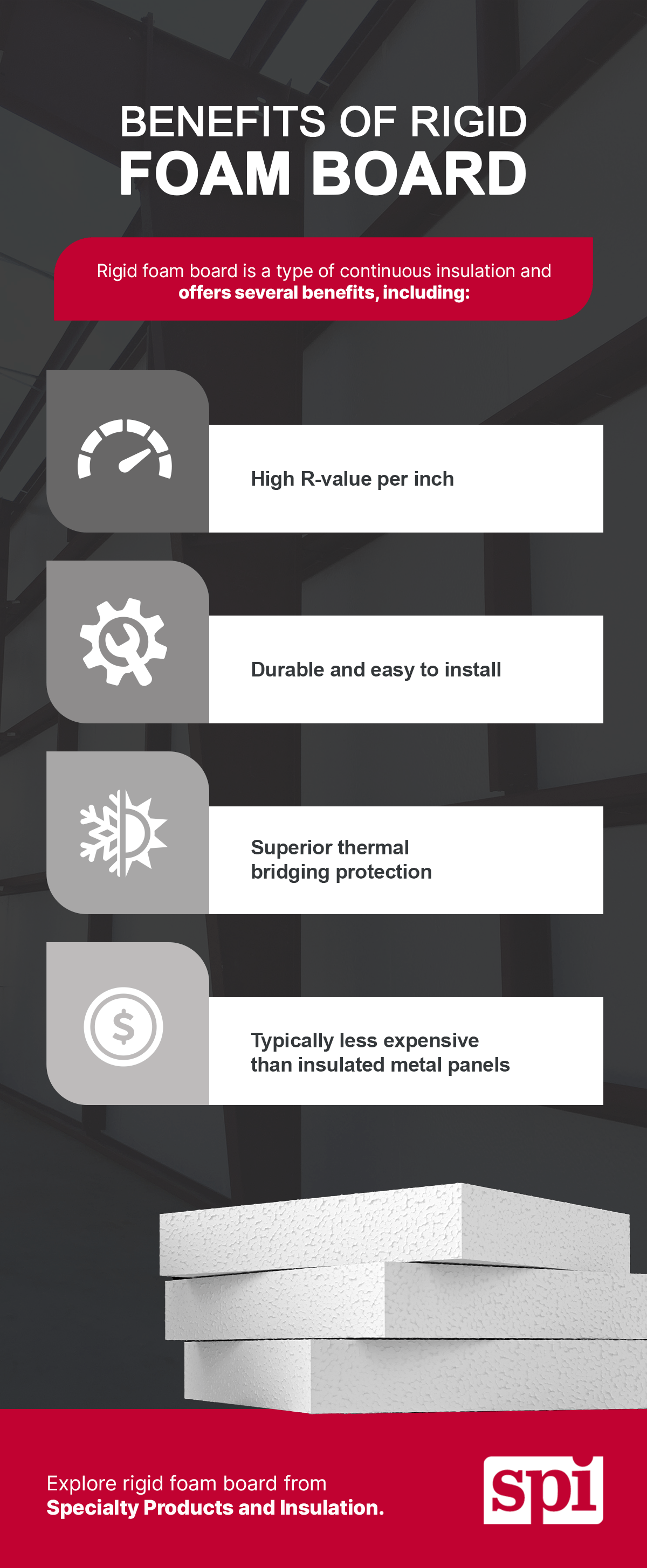

Rigid Foam Board

Rigid foam board is a type of continuous insulation and typically consists of a rigid polyisocyanurate or polyurethane foam core. Most rigid insulation systems can be used in both the roof and walls of metal buildings. Rigid board products are purchased in sheets and are installed on the exterior framing members of a metal building. Rigid foam board offers several benefits, including:

- •High R-value per inch

- •Durable and easy to install

- •Superior protection from thermal bridging, which occurs when a more conductive element creates an easy pathway for heat flow across a thermal barrier

Insulated Metal Panels

Insulated metal panels, or IMPs for short, consist of two prefabricated metal sandwich panels with a rigid polyurethane or polyisocyanurate foam core. Mineral wool is also used as the core insulation material in some insulated metal panel products, though rigid foam is more typical. IMPs are more commonly used in metal building walls but can also be used in the roof. Insulated Metal Panels pose several benefits, including:

- •More durable than other types of metal building insulation

- •Come in a wide variety of colors, finishes, and profiles

- •Provide continuous insulation throughout the building envelope

Insulated metal panels are the highest-cost metal building insulation option and often require heavy machinery during installation.

Reflective Insulation

Reflective insulation is comprised of a radiant barrier adhered to a fiberglass, foam, or bubble core. A radiant barrier is a reflective aluminum material used in metal buildings to reflect radiant heat from the sun and maintain a more stable indoor temperature. The radiant barrier reflects radiant heat away from the interior of the building in the summer months and toward the interior of the building in the winter. Several benefits of reflective insulation include:

- •Aids in condensation control

- •Stabilizes the interior temperature

- •Reduces noise and vibration

Reflective insulation is ideal for metal buildings in moderate climates and semi-conditioned buildings.

Mineral Wool

Mineral wool batts can be installed in metal building roofs and walls and are ideal for structures that store loud machinery, such as natural gas compressor stations, or in fire separation wall applications. Mineral wool is most commonly used in metal buildings with an additional insulation material, such as fiberglass, in order to comply with commercial energy code requirements. Most mineral wool insulation products are noncombustible and fire-resistant, and do not produce toxic smoke or promote flame spread. Mineral wool helps increase energy efficiency, improves thermal stability, and can reduce the impact of dangerous noise levels in both new construction and retrofit applications.

Spray Foam

Spray polyurethane foam, or spray foam for short, is most commonly used as a supplemental material to fill cavities in metal buildings but can also be used as a primary insulation method in smaller structures with through-fastened roofs. The chemical mixture is sprayed onto the interior of the roof and wall panels which creates a continuous thermal barrier. There are two classes of spray foam products: Open-cell and closed-cell foam, the latter of which is used more commonly in metal building applications as it better prevents condensation from forming on the steel framing. Spray foam should not be used as a primary insulation material for standing seam roofs, as it may restrict roof panel movement. When spray foam is used as the primary insulation material, several additional steps beyond other material applications should be taken, including (1) Informing the metal building manufacturer, as warranties may be affected; and (2) Demonstrating fire rating performance.

Explore Metal Insulation Products From Specialty Products and Insulation

Metal building insulation comes in a variety of material types, and there are many factors to consider when deciding which is best for your next project. The end-use of the building, project budget, and energy code requirements should be top-of-mind when selecting a metal building insulation product. We have a diverse range of insulation products for pre-engineered metal building systems and can help you choose the best option for your next job. Contact us today!